For me, hands down, my list starts with this one. Not because this is how I learned to weave or even because this is how I learned that weaving has cosmic possibilities. It's because I can't stop learning from this book and I love the beauty and intricacy of the ideas in this book. Sometimes I can't fathom what she's writing about, but I keep trying.

What's more important: Taking care of a book or reading it a lot?

I spent maybe a decade weaving my way through this one.

And writing notes on it -- in pen -- which is not very classy.

"Strickler," that's how weavers describe it, sort of like "Beyonce" or "Marilyn" -- a true star. This book is a delight and (in my humble opinion) belongs in your library if you have eight shafts. Maybe even if you don't.

Atwater -- another single-name star.

I think Mary Meigs Atwater single-handedly resurrected the art and craft of weaving in America in the 20th century. This is not hyperbole. We owe her almost everything (again, in my humble opinion). Published almost a century ago, the book is grandly and authoritatively titled: The Shuttle-Craft Book of American Hand-Weaving, Being an Account of the Rise, Development, Eclipse, and Modern Revival of a National Popular Art, Together with Information of Interest and Value to Collectors, Technical Notes for the Use of Weavers & a Large Collection of Historic Patterns. My edition is inscribed "Wayne Baker April 1951," a year before I was born.

Davison. Now that I think about it, ALL of the weaving classics

are known simply by the last name of the writer/weaver.

First published in 1944, my version is from the fourth printing in 1947. I treasure this book for several reasons -- among them, it's stamped with the name "Ruth C. Herron." She was a beloved member of our guild and a superb weaver, who continued to correspond with us from her late-in-life home in California, where she died at 107. I think of her often.

Even Ruth wrote in her books, albeit in pencil.

This book. We all have our heroes.

Is there anyone more loved among weavers than Anni Albers? From the Bauhaus to the gold medal for craftsmanship from the American Institute of Architects, the weaver who summoned us to "take a thread for a walk" and continues to teach us to this day. This book is her masterpiece, second only to her art.

Oh my gosh, I'm only at book number five. But this is a good time to pause and qualify my listings, to try and explain why I've chosen them. My list is by no means a "must have" for every weaver, or for beginning weavers, or even for a guild's weaving library. Not at all. These are just the books that I, at this moment in my life and in my weaving practice, love to have on my bookshelf. You might say these are my "desert island" books -- you know, if you were stranded on a desert island and could take only a handful of books with you, what would you choose? I'm also writing this as a sort of dialogue with you, the reader (assuming you've gotten this far), hoping you might, like me, appreciate the weaving books you love and perhaps even consider reading the books I've listed, if you haven't read them already.

(Not that I've read each book cover to cover. I'm really not that kind of a reader when it comes to books about our craft.)

So on down the list. And one more note: This list is not in any particular order of preference or value. It's just for perusement, as libraries themselves are.

I have to include Chandler. May the weaving goddesses bless this book,

because this is how so many of us learned to weave.

There was a time when I referred to Chandler as I was dressing my loom, as I learned to read drafts, as I was deciphering how to sley 16 ends per inch in a 12-dent reed, all of the basics. She gave us this gift and this book will always be in my library for that reason.

Wait, what? Not quite about weaving, but this book is

where I go down my own special rabbit-hole.

If you love dyeing, as I do -- and if you love creating textured weavings using shibori-resist techniques, as I do -- this book is another masterpiece, a weaver's companion. (Detour: There's a relatively new book out there, a brilliant book written by a former New Yorker writer who became a guard at the Met: All the Beauty in the World. You should read it, just saying.) Anyhow, this book by Yoshiko Wada presents all the beauty in the world of shibori. It's a big book, 9 1/2" high by 12" wide, with 211 pages of photos large and small, with information and inspiration about the magic and mystery of the Japanese art known as shibori.

Three more to go. This is hard and a lot of you may not agree at all. But I will press on. (Get it? Press, as in publish?)

Another book in my own area of interest: Ann Richards's definitive book on weaving dimensional textiles. She approaches her designs with a laser-like focus and creates beauty as a result.

Ann Richards of England is one of the luminaries in the field of dimensional weaving. I traveled to London to study with her, and that workshop plus this book gave me a foundation to build my own textured weavings. The joy is in the process, from start to finish: learning how to tame unruly threads as you dress your loom and then how to give them freedom as you weave so that they have room to move about in the finishing. And the finishing is a joy, as you see a fabric change almost organically in the water.

Sometimes the best books are those that continue to offer up insight and enjoyment well after you've read them -- or rather thought you read them.

There's a saying attributed to several sages: "When the student is ready, the teacher will appear." This book keeps bringing me lessons for new techniques -- and I've owned it for at least 20 years.

Ah yes, the old Weaver's magazine, perhaps one of the greatest how-to resources for weavers. Somehow I got my hands on the entire collection (which is another treasure, but not a book, that I could add to this list). Fabrics that Go Bump is a compendium of patterns and instructions that appeared in a number of issues, all focused on achieving bumps, pleats, ruffles, and billows in your fabric. I turn to this book often for inspiration and understanding.

So what's number 10? Stubenitsky once again!

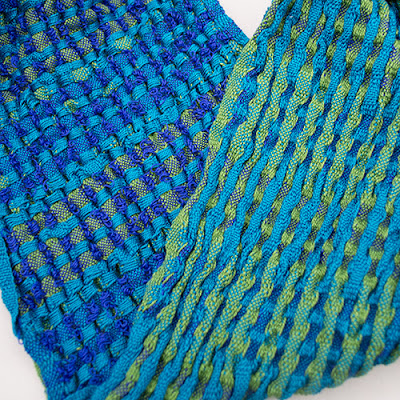

Why? Because it's crammed with originality and innovation

about one of my favorite techniques: deflected doubleweave.

Stubenitsky always lays a world before you, this time looking at the graphic, colorful, texture-full world of deflected doubleweave. (The woman is merciless when it comes to writing books: I think she's at five now, if you include Janna Weaves, and they're all abounding with patterns and ideas.) What I like about this book is that she offers a solid explanation for drafting DDW, which isn't as easy as it looks. One of my friends whose work appears in the book, when I asked how she arrived at her wonderful designs, told me she "played around a lot." And I understand exactly what she meant. There is a mystery to creating these designs and Stubenitsky helps de-mystify much of it.

That's my top ten. For right now, at least. What are yours? If you're like me, you have a library -- some of which you love, some of which you like, some of which you don't like but can't seem to part with. We need them for our work but we also need them as friends, it seems. That's what books are for.

I can't forget to mention my own book,

which is a favorite because I wrote it ;o)

Thanks for reading!

%20-%20Public.jpg)