How do you weave a countless number of structures on one warp? With an extended parallel threading, of course! This particular technique offers a lot of "bang for the buck" for weavers. All you have to do is modify your treadling and, in some cases, change the tie-up. If you're REALLY ambitious, you can change the tie-up and re-sley as well to achieve Double Weave or Shadow Weave.

What is an extended parallel threading? For those who follow the work of Marian Stubenitsky and/or Bonnie Inouye, it needs no introduction. For the rest of us, all it means is that, for starters, you use two colors in your warp, so that you can thread them A-B-A-B, etc. (A being your first color and B being your second). Then, instead of threading a straight draw of 1, 2, 3, 4, 5, 6, 7, 8 (just as an example), you thread your two colors using the same line, but separately, at a set interval.

For example, if you decide you're going to thread at an interval of 4, for an extended parallel threading on a straight draw, you will thread it this way: 1, 5, 2, 6, 3, 7, 4, 8, 5, 1, 6, 2, 7, 3, 8, 4, alternating between color A and color B. Here's a drawdown, by way of example. (I've posted it before, but it bears repeating.)

So your tie-up allows you to lift every other thread in an ascending twill order. This is the basic idea behind the structures I have been weaving. Because I like to paint warps -- and because I like to paint two separate warps in complementary but different palettes and beam them together and then thread them A-B-A-B in an extended parallel threading -- I decided to create an advancing point-twill using this technique.

Here are some drafts and photos of what I've weaving.

Variation #1: Echo

Here is the the drawdown, with a tie-up and treadling for Echo. Note that this is simply an advancing twill treadling.

And here is a photo of the sample I wove. You'll see that I didn't weave the entire treadling, because I was just trying to get an idea of how it would look.

Variation #2: Echo

Next treadling for Echo, same tie-up. This treadling is for an advancing-point twill.

My woven sample, below. I love the way the pattern seems to sparkle, which enhances the color shifts.

Next, I crawled under the treadles to do another tie-up. (Truth be told, I usually make an error when I'm tying up and have to start all over again. Which causes a lot of sweating and cursing, which is not to be written about in a blog post.)

Variation #3: Doubleweave

Here is the drawdown for treadling as doubleweave. I will not show you my sample, as I really messed up! I had to re-sley the reed to make the warp ends much denser -- and somewhere along the way my shed got really boggled up. I do have a sample, but again, not for public consumption ;o)

Yes, this would work well with a collapse-cloth technique, with one layer shrinking and pulling in while the other layer would "pouf" and add texture. Even with the poor shed I had -- owing mostly to the fact that I was using two different devices (Texsolv and metal hooks) to tie up my treadles and their lengths varied -- I could tell from my sample that this design has promise.

Variations #4 and #5: Jin

Then I got down under the loom and re-did my tie-up to weave Jin -- one of my favorite structures because it is so versatile. Here's the first treadling I used. If you look at the treadling, you'll see that, if you remove the tabby, it's the same advancing-twill sequence as in variation #1 above.

And here is the second treadling, an advancing point-twill. Again, if you take away the tabby, it's exactly like variation #2 for Echo.

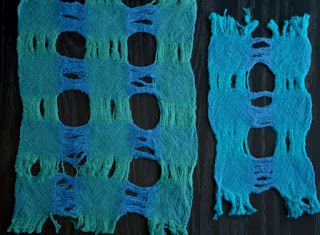

Here is how the two samples wove up. (The first treadling appears at the bottom of the photo and the second is at the top.)

Variation #6: Jin

Here's yet another treadling, the results of which I love!

The sample:

Variation #7: Rep

There are a countless variations for an extended-parallel threading like this. One additional structure I did not mention was shadow weave. Here's a drawdown I came up with.

However, this post is getting way too long and it's taking way too much time! Suffice it to say that I'm hoping to create a workshop out of this. And as for all the samples I have been weaving: I beamed a 12-yard warp, 46" wide, using 20/2 silk sett at 40 ends per inch. The weft is, for the most part, 60/2 silk.

I'm weaving yardage for a garment. Most likely, I will use four or five different treadlings for Jin -- I might even add a networked treadling in there somewhere -- and alternate them randomly throughout the fabric. I can't choose just one, so I have to weave them all.

And here's the photo that inspired this project to begin with. I can't attribute it to any source, because I found it on the internet long ago. The combination of pinks and greens is irresistible!